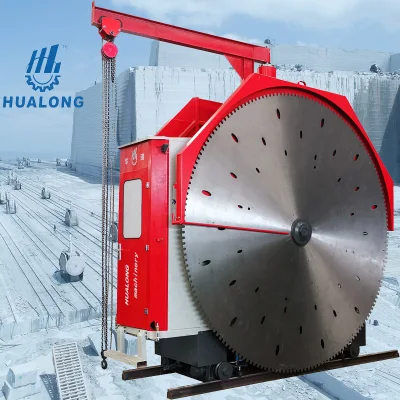

CE Certified Hualong Stone Cutting Machinery Automatic 380V/220V High Efficiency/Speed Double Blade Granite Marble Quarry Stone Block Mining Machine

Description

Basic Info

| Model NO. | 2QYKZ series |

| After-sales Service | Provided |

| Warranty | 1 Year |

| Slide Way | 4 Steel Cylinders |

| Power of Main Motor | 66X2 Kw |

| Power of Raiway Switch Motor | 0.75X2 Kw |

| Weight | 7500-10000 Kgs |

| Dimension(L*W*H) | 380X220X290cm |

| Warranty of Core Components | 1 Year |

| Voltage | 380V-AC |

| Marketing Type | New Product 2020 |

| Cutting Width | 1360-3200mm |

| Cutting Thickness (Max) | 1550mm |

| Power | 139.2 Kw |

| Power of Stroke Motor | 2.2 Kw |

| Blade Diameter | 3600mm |

| Power of Pump Motor | 3.5 Kw |

| Transport Package | 1) Covered by PE Film Wholely. 2) Packed in Plywoo |

| Specification | 380X220X290cm |

| Trademark | Hualong |

| Origin | Fujian, China |

| Production Capacity | 150 Set/Sets Per Month, High |

Packaging & Delivery

Package size per unit product 380.00cm * 220.00cm * 290.00cm Gross weight per unit product 7500.000kgProduct Description

2QYKZ series Quarry Stone Cutting Machine, new developed with double main permanent magnet motors regulated by frequency converters, dual big blades and 4 shaft transmission, is powerful and high efficient for mining granite at quarry, also good for mining marble, quartz...

Main Features:

1) Equipped with powerfull permament magnet motors with high rated speed of 11000 rpm and high reliability.2) To regulate the main motors speed by frequency converter, make it possible to adjust cutting speed according to the hardness of the stone cutted.

3) Productivity improved 10% + higher.4) 10-15% energy saving than 2QYKT series.5) Safer, more stable.

| Technical Data | |||||

| Model No. | 2QYKZ-3600A | 2QYKZ-3600B | 2QYKZ-3600C | 2QYKZ-3600D | |

| Blade diameter | mm | 3600 | |||

| Max.cutting depth | mm | 1500 | |||

| Width of cutting | mm | 1360-1900 | 1500-2000 | 2200-2700 | 2700-3200 |

| Power of main motor | kw | 66 x 2 | |||

| Power of pump motor | kw | 3.5 | |||

| Power of stroke motor | kw | 2.2 | |||

| Power of railway switch motor | kw | 0.75x2 | |||

| Gross Power | kw | 151 | |||

| Gross weight | kg | 7000-9000 | |||

| Dimenssion (L x W x H) | mm | 3900x1600x2900 | |||

| More Models | Max. cutting depth | Blade diameter | Gross power | Remarks | |

| 2QYK-3800 | 550 mm | 1350 mm | 50.8 kw | W/ normal motors | |

| 2QYKZ-3800 | 1600 mm | 3800 mm | 151 kw | ||

| 2QYKZ-4200 | 1800 mm | 4200 mm | 151 kw | ||

| 2QYKZ-4600 | 2000 mm | 4600 mm | 167 kw | ||

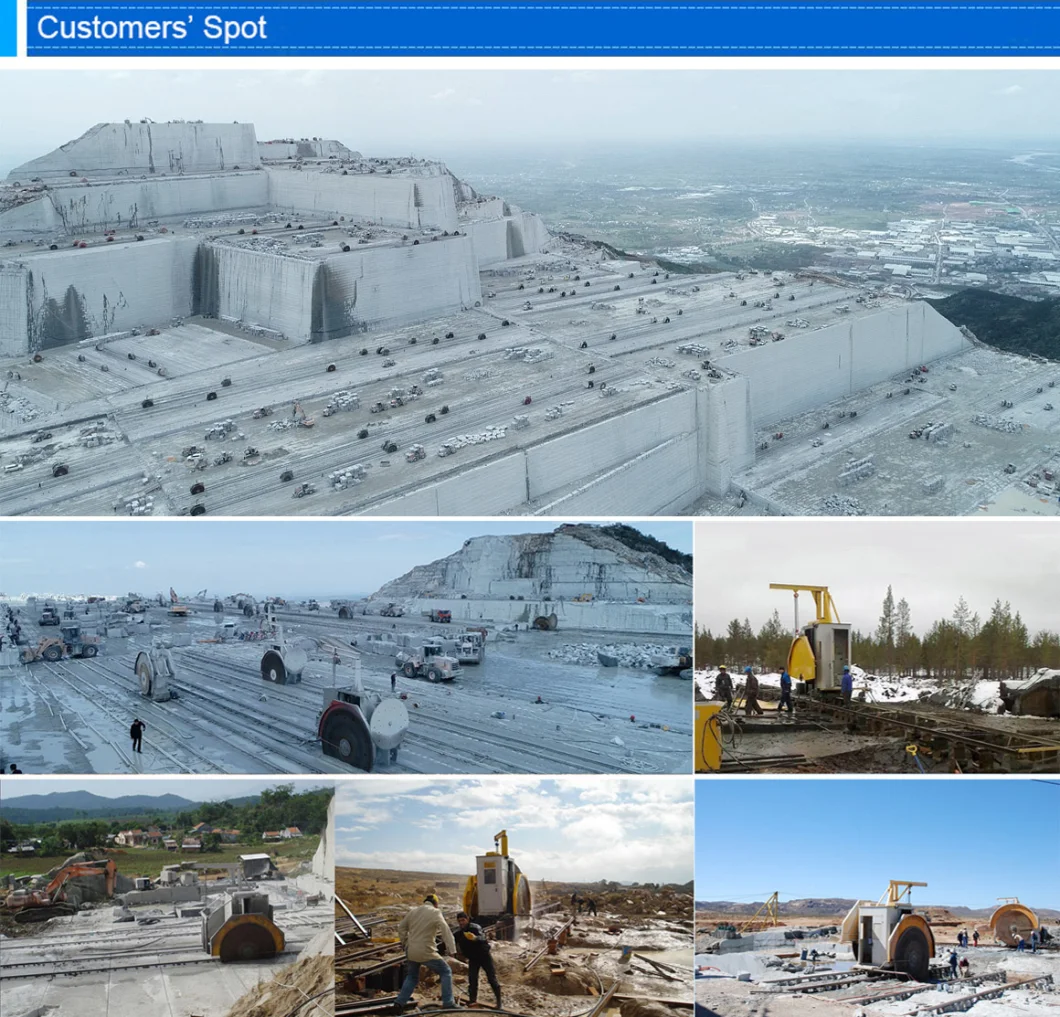

Why choose Hualong stone mining machine?

* High speed --- It can cut est. 15 sqm/hour, while the wire saw cuts about 10 sqm/hour.

* Low consumption --- It cost about USD1.00/sqm, while the wire saw cost USD1.5-2.3/sqm.* Quality Assurance--- Made with 25 years+ expertise and patents.--- Strictly conforming to ISO9001:2105 quality management system.* On-purchase Service--- Many machines available for choice.--- Customization available--- Experienced techs for all your questions.* After-sale Service--- Parts & Accessories Quick supply for needs--- Troubleshooting by phone, e-mail, or WhatsApp/Wechat--- Installation and operation training for any machine--- Qualified and experienced technicians available to overseas

Details Images

Power Connection & Operation Panel

Brand: Siemens, Sunye, Sinee, RmspoOriginal: ChinaQuality certificated by CEFrequency Converter regulates motor speed change according to hardness of materials cutted, improving productivity much more.

Touch Screen (Optional)

Touch screen with upgraded function which can adjust cutting speed automatically and steadly. It reduces mechanical impact load and wear, stablize saw cutting, and improves mining efficiency

Touch Screen (Optional)

Touch screen with upgraded function which can adjust cutting speed automatically and steadly. It reduces mechanical impact load and wear, stablize saw cutting, and improves mining efficiency

Power Transmission System

No need v-belt.

This is a patent structure for better power uitilization and work stability. A group of 4 gear shafts couple tightly, transmit themotors' power to the double blades steadily and more efficiently for cutting.

Main Motors

Name: Permanent Magnet motorBrand: CETLEfficiency: 96%Original: ChinaDomestic famous engines, 66 kw, high rated speed at 11000 rpm, wide range of speed control and high reliability.

Advantage of Blade with Cut hole design

1) Reduce dead weight, reduce load, reduce power loss by about 40%.2) Both convenient with cooling water into the joint, enhance the cooling effect of the saw blade deformation, and better will bethe joint sand discharge, but also can release the stress generated in the use, more resistant to deformation, longer life

| Our Service | |

Pre-Sales Service * Inquiry and consulting support.* Configure best machine line according customer condition* View our Factory. | After-Sales Service * Training how to instal the machine, training how to use the machine.* Engineers available to service machinery overseas.* Lifetime technology maintenance in free and spare parts supply. Related Products |

A: 3000(diameter of blade)/2 -300mm(deductive parameter) = 1200mm

Q: How depth can the double blade machine cut per trip?

A: 150-200-250mm depand on the hardness of the stone cutted.

Q: How fast can 2QYK-3600 double blade machine cut along with the rail?

A: 200m per day for marble, 150m per day for granite, based on cutting 20 hours per day.

Q: How width can the double blade machine cut?

A: The double blade can stretch out and cut 1360-3200mm wide depanded on different types.

Q: How many stone can be mined by one double blade machine per month?

A: About 4500-5000 gross cbm per machine if work 15-20 days day and night.

Q: We have a stone quarry. How many double blade machines are needed for our mining

A: One machine per 3000 sqm working area is suggested to equip.

Q: How long rails should be equipped for the double balde machine?

A: 300 meter rails for one machine.

Q: How many blades should be equipped for the double blade machine?

A: Two sets for one machine, or Three sets for two machines.

Q: How many pieces of blade per set?

A: 4 pieces, including double small blades of 2200-2400 mm diameter for initial cutting and taking track shape, and double big blades for further deeper cutting.

Q: How long can a blade work without changing the diamond segments (blade tips)?

A: For cutting granite at 1500mm depth, the blade should be changed after the machine walking about 400 meters. For cutting marble, should be changed after walking about 1000-2000 meters.

Prev: Laser Bridge CNC Type Stone Cutting Machine for Granite

Next: Bcmc Saw Blade Diamond Segment Hot Pressed Sintered for Marble Granite Concrete Basalt Stone Cutting

Our Contact