EPS Foam Machinery Block Automatic Styrofoam Cutting with Foam Cutter Hot Wire

Description

Basic Info

| Model NO. | ESC200-800 |

| Computerized | Computerized |

| Certification | CE |

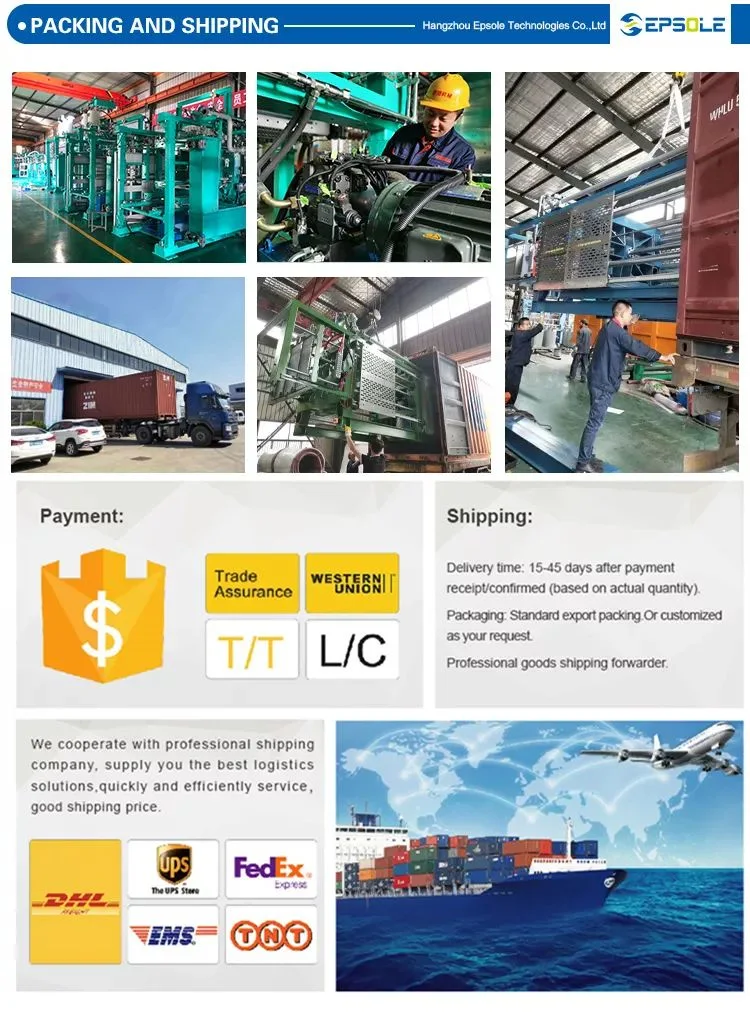

| Transport Package | Ocean Shipping |

| Trademark | EPSOLE |

| Origin | China |

| Production Capacity | 150 Set / Year |

Product Description

Product Details

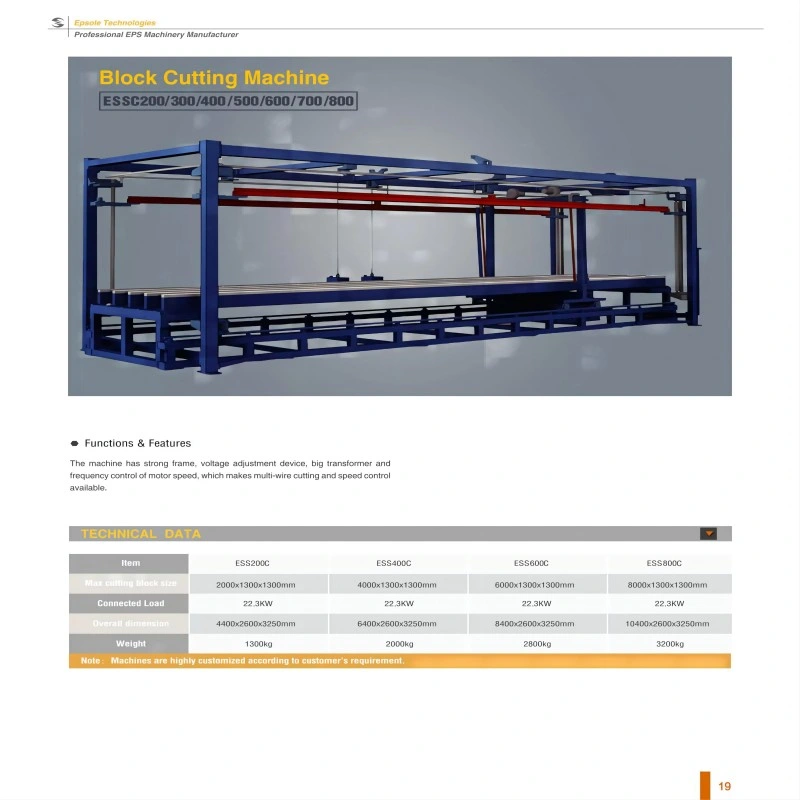

CUTTING MACHINEType: ESC6000C Automatic type Machineoverall dimension:9,600 x 2,600 x 3,250mmThree-direction cutting, horizontal, vertical and cross cuttingMax 30 cutting wires can be manually set in horizontal direction,and max 15 cutting wires in vertical directionMinimum thickness to be cut is 10mmSuit for cutting Block size:6,000x1,500x1,500mmSuit for different density block Cutting speed: 0~2m/min,Capacity :denisity15g/l,block size 3,000x1500x1500mm,cut time:8~12min Connect load: 22.3kwNote: 1. with automatic down cutting system2. with block aligning device, keep block in straight position.

ATTENTION

1.EPS block should be dried before cutting to increase efficiency and avoid damage of hot wires;2.Check cutting machine before operation to ensure reliability of ground connection, correct running direction of main cutter, air blower and limit switch;3.Strictly prevent foam beads and cutting fragments entering into the electric system to avoid conflagration because this equipment is a strong electric current working system;4.Maintenance and attention points of variable-speed gear box.5.Replace lubricating oil in gear box every half a year.6.Keep enough lubrication oil in oil tank and check it regularly;7.Pay attention to running condition of whole equipment during its working, Stop to check when there is any unusual situation.8.Notice: Do not whack the gear box.9.Fire Extinguisher must be prepared at working site and operator should monitor the machine during operation;10.Operators is allowed to operate after training.

Our Contact