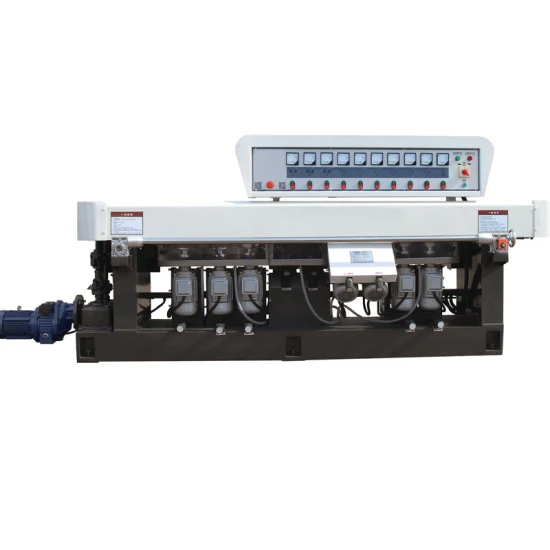

Manual Control Glass Edge Edging Polishing Machine

Product Description ZK9325 glass linear edging machine Equipment Features: 1.The ZK9325 glass linear edging machine can

Description

Basic Info

| Model NO. | ZK9325 |

| Warranty | One Year |

| Type | Glass Edging Machine |

| Certification | CE, ISO, FDA, UR, PCI, PDA, SGS |

| Structure | Vertical |

| Control System | Industrial Computer |

| Glass Washing Machine Type | Glass Edging Machine |

| Glass Edging Machine Type | Glass Straight Edging Machine |

| Condition | New |

| After-sales Service | Lifetime Warranty |

| Min.Glass Size | 100*100mm |

| Max.Glass Size | 3000*3000mm |

| Glass Thickness | 3-25mm |

| Feeding Speeds | 0.5m/Min-6m/Min |

| Power | 195kw |

| Worktable Height | 750mm |

| Power Supply | 380V, 50Hz |

| Max Arris Width | 25mm |

| Max.Cutting Edging | 3mm |

| Angular Angle | 45 Degree |

| Voltage | 220V, 380V, 415V, Customised |

| Frequency | 50Hz, 60Hz, Customised |

| Color | Blue, Customised |

| Length | 6.8m |

| Width | 1m |

| Transport Package | Wooden Box, Steel Frame |

| Specification | 6.8m* 1m*2.5m |

| Trademark | Zhengke |

| Origin | Shandong, China |

| HS Code | 8464201000 |

| Production Capacity | 10000sets/Year |

Product Description

Product Description

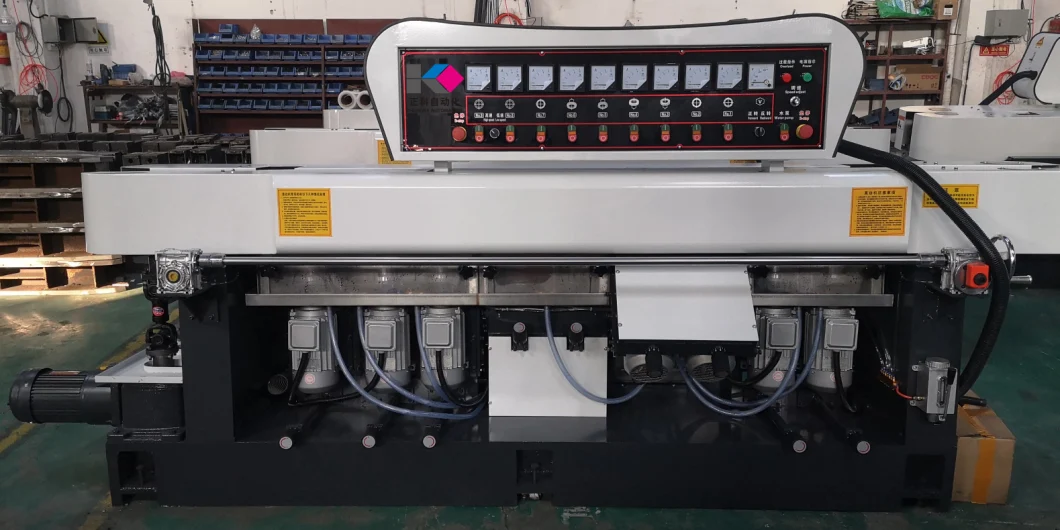

ZK9325 glass linear edging machine

| Voltage | 380V,220V,customized | Frequency | 50HZ,60HZ,customized |

| Power | 19.5kW | Max.glass size | 3000mm×3000mm |

| Min.glass size | 100×100mm | Glass thickness | 3-25mm |

| Max.cutting edging | 3mm | Feeding speeds | 0.5m/min-6m/min |

| Max arris width | 2 5mm | Arris angle | 45° |

| Worktable Height | 750mm | Overall dimension | 6.8m× 1m×2.5m |

Equipment Features:

1.The ZK9325 glass linear edging machine can be used to grind flat glass of different sizes and thicknesses, and can process glass with straight edges and 45 degree edges.

2.This machine integrates multiple functions of rough grinding, fine grinding and polishing, and adopts stepless variable speed adjustment, with large adjustable range and stable variable speed. During the grinding process, the feed speed and feed rate can be adjusted at will, and the front guide rail can also be adjusted to change the thickness of processed glass.

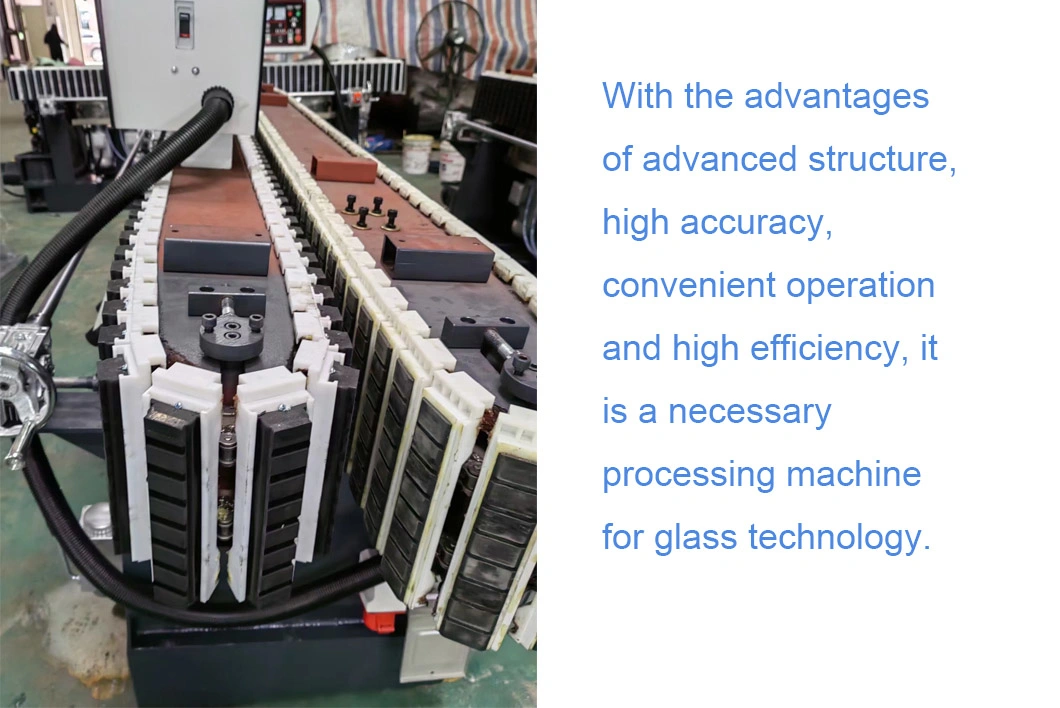

3.With the advantages of advanced structure, high accuracy, convenient operation and high efficiency, it is a necessary processing machine for glass technology.

4.The whole machine of the equipment is equipped with automatic oil filling system to prevent the motor and girder from sliding due to long service time.

Details Photos

Applicaton

1.Sink hole in the glass countertop of the cabinet, stove hole, pipe hole

2.Shower door clamp,hinge hole, handle hole, cut outs

3.Cabinet kitchen door invisible handle hole

4.Aluminum profile handle hole and hinge hole

5.Electric panel

6.Aquarium stealthy cover, fish tank making etc.

7.Boothroom mirror back processing, one part of function as sandblasting

Sample Photos

Package and Transpor

Factory WorkshopShandong Zhengke Automation was founded in 2014, located in Jiyang Industrial Park, Jinan, Shandong Province. The company covers an area of (5000) square meters, the core team of 50 people. Have independent technology design, research and development team. Have modern office space. Is the domestic professional glass machinery high-tech enterprises.The company mainly produces insulating glass equipment, distribution of glass cutting, edging equipment, toughening, laminating and other related equipment. The company has more than 1500 terminal customers, with good reputation, won the recognition of the majority of customers.We have 2 independent technical patents, 12 Copyrights and 2 trademarks. The company developed a series of two-component glue machine advanced technology, sensitive reversing, continuous stability, high production efficiency, high degree of automation, easy to use; Widely used in two-component silicone structural adhesive, polysulfide adhesive, polyamine glue and other high accurate ratio, uniform mixing and fast operation occasions. Solve the phenomenon of high waste and low efficiency caused by manual work, is the ideal glass bonding production equipment.The company adheres to the business philosophy of "Honest and trustworthy, and prosper enterprises with science and technology", based on talent, technology, service and reputation, not only to provide customers with high quality glue coating equipment, but also to provide you with case debugging equipment, technical consulting guides, staff operation training and other comprehensive after-sales service, so as to relieve customers of worries.

Our Advantages

1.We provide professional glass production solutions.

2.Professional online service team, any mail or message will reply within 24 hours.

3.We have a strong team provide wholehearted service to customer at any time.

4.We insist on Customer is Supreme, Staff toward Happiness.

5.Put the Quality as the first consideration;

6.OEM & ODM, customized design/logo/brand and package are acceptable.

7.Advanced production equipment, strict quality testing and control system to make sure superior quality.

8.Competitive price: we are a professional glass machine manufacturer in China, there is no middleman's profit, and you can get the most competitive price from us.

9.Good quality: good quality can be guaranteed, it will help you keep the market share well.

10.Fast delivery time: we have our own factory and professional manufacturer, which save your time to discuss with trading companies. We will try our best to meet your request.

Prev: Track Mounted Mobile Crushing and Screening Portable Stone Crusher Machine

Next: Zxm-C251 Glass Beveling Machine with Grinding Beveling and Polishing Function

Our Contact

Send now