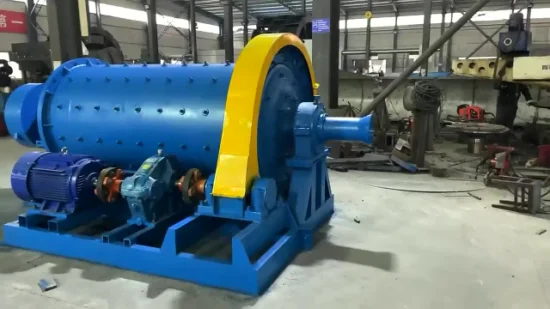

Stone Grinding Small Capacity 2-3 T/H Ball Mill Machine for Mining Quarry

Description

Basic Info

| Model NO. | BM |

| Type | Ball Mill |

| Motor Type | AC Motor |

| Motor Power | 15KW |

| Rotationl Speed | 32r/Min |

| Application | Mine |

| Materials | Ore |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | Warranty&Technology |

| Name | Ball Mill |

| Model | 600*1200 |

| Rotating Speed | 32r/Min |

| Ball Loading | 1-2t |

| Feeding Size | 0-20mm |

| Output Size | 0.075-0.89mm |

| Capacity | 1-2t/H |

| Price | Competitive |

| The Machines Classification | Ball Mill Grinding Equipment |

| Grinding Way | Dry or Wet Steel Ball Grinding |

| Feature | Fine Powder Discharge |

| Usage | Grinding Mining Hard Ore |

| Grinding Media | Manganese Steel Ball |

| Processed Materials | Mine Ore |

| Feature 2 | Abrasion Resistance |

| Transport Package | Iron Frame or Customer Request |

| Specification | 3843*1850*1400mm |

| Trademark | WKD |

| Origin | China |

| HS Code | 8474100000 |

| Production Capacity | 1000sets/Year |

Packaging & Delivery

Package size per unit product 45.00cm * 45.00cm * 45.00cm Gross weight per unit product 45.000kgProduct Description

Introduction

Raw Material Ball Mill also named as grinding ball mill, raw material mill, material grinding mill, and clinker mill, is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal, and glass ceramics, and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

| Model | The chamber speed(r/min) | Ball Load (t) | Feed In Size (mm) | Feed Out Size (mm) | Capacity (t/h) | Motor Power (kw) | Weight (t) |

| 900 ×1800 | 38 | 1.5 | ≤ 20 | 0.075-0.89 | 0.65-2 | 18.5 | 3.6 |

| 900 ×3000 | 38 | 2.6 | ≤ 20 | 0.075-0.89 | 1.1-3.5 | 22 | 4.6 |

| 1200 ×2400 | 35 | 3.5 | ≤ 25 | 0.075-0.6 | 1.5-4.8 | 37 | 11 |

| 1200 ×3000 | 35 | 5 | ≤ 25 | 0.075-0.4 | 1.6-5 | 45 | 13.8 |

| 1200 ×4500 | 35 | 7.5 | ≤ 25 | 0.075-0.4 | 1.6-5.8 | 55 | 14 |

| 1500 ×3000 | 27 | 8 | ≤ 25 | 0.075-0.4 | 2-5 | 75 | 15 |

| 1500 ×4500 | 27 | 12 | ≤ 25 | 0.075-0.4 | 3-6 | 95 | 18 |

| 1500 ×5700 | 27 | 15 | ≤ 25 | 0.075-0.4 | 3.5-6 | 130 | 21.7 |

| 1830 ×3000 | 24 | 12 | ≤ 25 | 0.075-0.4 | 4-10 | 185 | 28 |

| 1830 ×6400 | 24 | 23 | ≤ 25 | 0.075-0.4 | 6.5-15 | 210 | 34 |

| 1830 ×7000 | 24 | 25 | ≤ 25 | 0.075-0.4 | 7.5-17 | 245 | 36 |

| 2100 ×6500 | 21 | 31 | ≤ 25 | 0.075-0.4 | 14-26 | 355 | 52.8 |

| 2200 ×7000 | 21 | 37.6 | ≤ 25 | 0.075-0.4 | 15-28 | 400 | 56 |

| 2700 ×7000 | 18 | 61.8 | ≤ 25 | 0.075-0.4 | 18-35 | 710 | 73 |

Working principle

The ball mill is a horizontal rotating device transmitted by the outer gear

The materials are transferred to the grinding chamber through the quill shaft uniformly There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by the barrel rotation brings the steel balls to a certain height and impacts and grinds the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Features

The ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powder-making production line including cement, silicate, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics and the ball mill can grind various ores and other materials with dry type and wet type. There are two kinds of ball mills, grate type and overflow type due to different ways of discharging material.

1) Suitable for grinding material with high hardness2) The shape of the final products is circular3) No pollution for the powder with ceramic ball4) Stable performance Easy installation5) The capacity and fineness can be adjusted by adjusting the diameter of the ball.

Company Information

Victor is a large mineral processing manufacturer for 15 years history, with covering an area of 48,000 square meters and 20,000 square meters for workshop, with various large modernized machinery facilities, professional R&D team and installation team.

With 32% market share in China and the rest to overseas, already successfully exported to over 50 countries, such as USA, England, Australia, Brazil, Turkey, Italy, Russia, South Africa, Zimbabwe, Sudan, Ghana, Congo, Morocco, India,Indonesia, Malaysia, Philippines, North Korea, Mongolia, Vietnam, Thailand etc.

Our goal is to provide one-stop service for you and assist you to solve all problems from investment to his return in the field of mining, including the preliminary mineral analysis, mineral processing test, engineering design, equipment debugging and technical training etc.. We are expert especially at mining separating and lab mining plant, main products as below:Gold trommel wash plantShaking tableSpiral chute separatorCentrifugal gold concentratorJig separator machinesWaste recycling machineGrinding and mill crusherFlotation cell machineMagnetic separatorLaboratory mining plantTo View More

Our Service:1) Pre-sale service: Freely provide project designing, process designing, choosing suitable equipment for you.2) Medium-sales service: Accompany you to complete the acceptance of the equipment, draft the construction scheme and detailed process, and complete process of export3) After-sales service: Offer considerate technical guidance in installation, debugging and operators training. We are available at any time if you need. Q1:Are you a manufacturer of mining equipment?A1:YES, with more than 15 years production & sales experience Q2: Could your company help design mineral flow chart?A2: YES, we have about 20 people team of technician and can design a whole set of processing line. Q3: Can you provide sample testing?A3: YES, we have mineral testing laboratory and can do sample testing for you. Q4: For efficient communication, what information should you provide before quotation?1) what's your processed material? if it's rock ore, do you have mineral report?2) what's your capacity(tons per hours)?

Our Contact