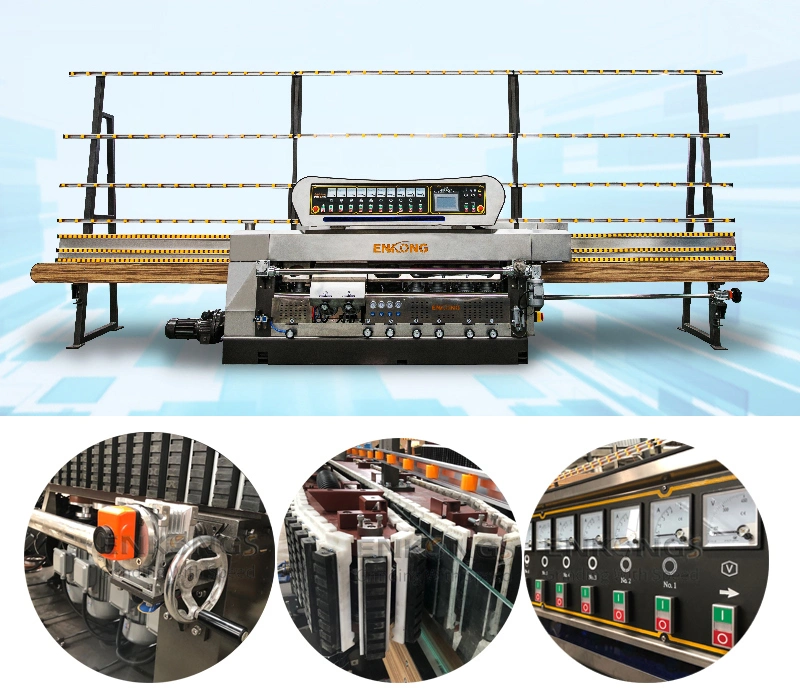

Zm 9 Manual Control Glass Edge Edging Polishing Machine

ZM 9 Glass Straight Line Edging Machine 1. ZM9 is suitable for processing straight-line edge & 45°arrises of glass sheet

Description

Basic Info

| Model NO. | ZM9 |

| Condition | New |

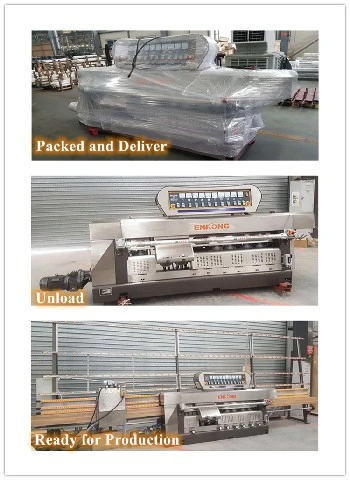

| Transport Package | Suitable for Container Load |

| Specification | packing size: 3000*1000*1500; 2800kgs |

| Trademark | ENKONG, ENKONGS |

| Origin | Made in China |

| HS Code | 8464109000 |

| Production Capacity | 50sets/M |

Product Description

ZM 9 Glass Straight Line Edging Machine

| Technical Specifications (ZM9) | |

| Spindles | 9PCS |

| Processing glass thickness | 3~25mm |

| Angle of arris | 45° |

| Min. size of glass | 80mm×80mm |

| Processing speed | 1.26~6.0 m/min |

| Installed power | 19.08KW |

| Weight | 2650KG |

| Dimension: | 7000×1400×2500mm |

1. ZM9 is suitable for processing straight-line edge & 45°arrises of glass sheet with various size and thickness.

2. A special design of the in-feed section for controlling the desired amount of glass removal without adjusting each spindle individually.

3. Independent felt wheel and the cerium water recirculation system make the flat edge more shining.

4. Input and output conveyor adopt timing belt which can improve the transmission precision.

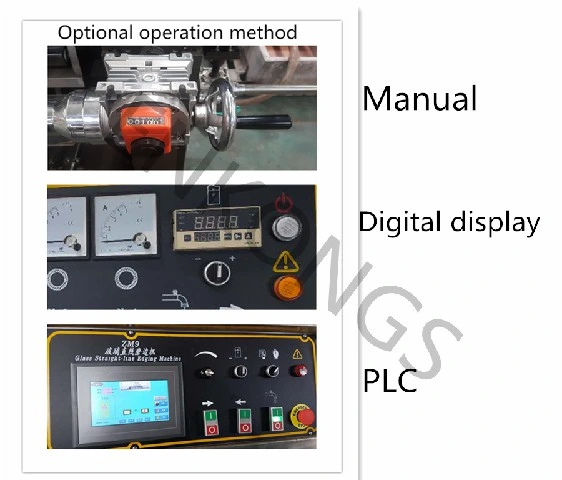

5. It is easy to operate and has good performance.

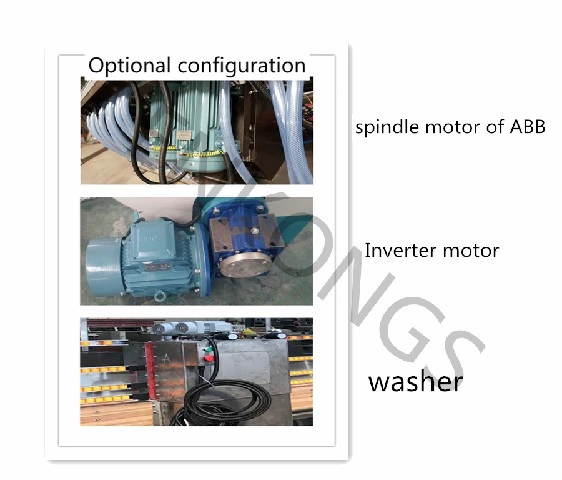

6. All grinding motor used Cannoon Motor. And the motor with longer service life.

7. The spindle with good and stable structure. And it has better waterproof.

Wheels disposal:

| No.1 | Diamond wheel |

| No.2 | Diamond wheel |

| No.3 | Resin wheel |

| No.4 | Fine grinding wheel 10S40 (Made in Italy) |

| No.5 | Front arris resin wheel |

| No.6 | Front arris 10S40 wheel (Made in Italy) |

| No.7 | Rear arris resin wheel |

| No.8 | Rear arris10S40 wheel (Made in Italy) |

| No.9 | Wool felt wheel with cerium oxide (Made in Italy)/CE 3 polishing wheel |

1. ZM9 is suitable for processing straight-line edge & 45°arrises of glass sheet with various size and thickness.

2. A special design of the in-feed section for controlling the desired amount of glass removal without adjusting

each spindle individually.

3. Independent felt wheel and the cerium water recirculation system make the flat edge more shining.

4. Input and output conveyor adopt timing belt which can improve the transmission precision.

5. It is easy to operate and has good performance.

Our Contact

Send now