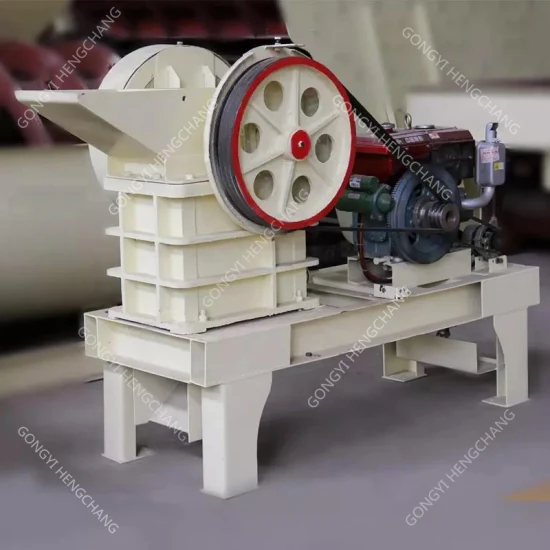

Hot Selling Mining Machinery Mobile Portable Mini Small Rock Stone Mine Crushing Quarry Limestone Ore Gold Widely Used Hydraulic Jaw Crusher Machine for Sale

Jaw Crusher Application Jaw Crusher Detail Jaw Crusher Feature Advantage Jaw Crusher Working principle Company Profile C

Description

Basic Info

| Model NO. | PE250x400 ~ PE1200x1500 |

| Type | Jaw Crusher |

| Motor Type | AC Motor |

| Motor Power | 75kw |

| Application | Highway |

| Materials | Limestone |

| Outlet Size | 20-50mm |

| Inlet Size | 600×900mm |

| Condition | New |

| Warranty | 3year |

| After-sales Service | Video Technical Support, Engineers Available to Se |

| Max Feeding Size | 200-1520mm |

| The Machines Classification | Diesel Engine Mobile |

| Dimension(L*W*H) | 1800*1060*2100mm |

| Voltage | 380-440V/50-60Hz Three Phase Alternating |

| Output Size | 95-165mm |

| Application Material | Gold, Granite, Marble, Limes |

| Range of Discharge Opening | 20-275mm |

| Application1 | Mining, Metallurgy, Building, High Wa |

| Feed Opening Size | 250*400mm |

| Model | PE250X400 ~ PE1200X1500 |

| Processed Materials | 200 Kinds Materials(<300 MPa) |

| Transport Package | Standard Packing |

| Specification | ISO9001: 2008 |

| Trademark | Hengchang |

| Origin | China |

| HS Code | 8474209000 |

| Production Capacity | 300 Set/Sets Per Month |

Product Description

| Hot selling mining machinery mobile portable mini small rock stone mine crushing quarry limestone ore gold widely used hydraulic jaw crusher machine for sale |

| Jaw crusher is an efficient and energy-saving crushing equipment, divided into two kinds: coarse and fine broken, PEF series is used for coarse breaking, and PEX series is used for medium and fine breaking.Has the advantages of large crushing ratio, simple structure, reliable work, easy manufacture, convenient maintenance, etc. |

Jaw Crusher Application

| It is capable of breaking any material with compressive strength under 320Mpa, such as limestone, basalt, granite, marble, iron ore, coal, gypsum, and has been widely used in the industries of mining, metallurgy, building materials, highway, railway, water conservancy and chemical industry. |

| Applicable materials:Stone crusher is used for crushing over 120 kinds of rocks, such as limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregate etc. Different final output size could meet your different needs. |

Jaw Crusher Detail

| 1)Simple structure, convenient in use and maintenance. Stable performance, low operation cost, high crushing ratio.2)Crushing cavity depth and no blind spot, increasing the feeding ability and capacity.3)High crushing ratio, uniform product size.4)Gasket type discharging mouth adjusting device, reliable, convenient and the adjust ingrange is big, increase the flexibility of the equipment.5)Lubrication system safe and reliable, easy to parts replacement, small maintenance workload.6)Simple structure, reliable operation, low operating costs.7)Energy saving: stand-alone energy saving 15% ~ 30%, the system energy saving more than double.8)Discharging mouth wide adjustment range, can meet the requirements of different users.9)Low noise, little dust. |

Jaw Crusher Feature Advantage

| 1.The jaw crusher cavity is deep and there is no dead zone, which improves the feeding capacity and output; 2.The crushing ratio is large and the product size is uniform; 3.Gasket-type discharge opening adjustment device is reliable and convenient, with a large adjustment range, which increases the flexibility of the equipment; 4.The lubrication system is safe and reliable, the replacement of parts is convenient;5.Simple structure, reliable work, low operating cost;6.Equipment energy saving: single machine energy saving 15%~30%; 7.The adjustment range of the discharge opening is large, which can meet the requirements of different users; 8. Low noise and less dust. |

Jaw Crusher Working principle

| Jaw crusher machine uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the triangle belt and slot wheel to make the moving jaw plate move by a regulated track. Therefore, the materials in the crushing cavity ,which is composed of fixed jaw plate, moving jaw plate and side liner,can be crushed and discharged through the discharging opening. |

| Model | Max.feed size(mm) | Adjustment range(mm) | Capacity(t/h) | Main shaft(r/min) |

| PE150X250 | 125 | 10-40 | 1-3 | 285 |

| PE200X300 | 165 | 20-70 | 2-8 | 265 |

| PE250X400 | 210 | 20-80 | 5-20 | 310 |

| PE400X600 | 340 | 40-90 | 10-40 | 275 |

| PE350X750 | 290 | 30-55 | 20-50 | 255 |

| PE500X750 | 425 | 50-100 | 34-68 | 250 |

| PE600X900 | 480 | 75-200 | 40-120 | 250 |

| PE750X1060 | 630 | 80-200 | 80-160 | 250 |

| PE900X1200 | 750 | 100-200 | 110-200 | 200 |

| PE1000X1200 | 850 | 195-265 | 315-500 | 180 |

| PE1200X1500 | 1020 | 150-300 | 400-800 | 300 |

Company Profile

| Gongyi Hengchang Metallurgy Building Material Equipments plant was built in 1992, a professional manufacturer specializing in the production of coal slurry dryer, coal slime dryer , coal dryer ,sawdust dryer , fly ash dryer , slag dryer ,vinasse dryer and so on.We have professional engineers and experienced workers in our factory, we ensure that we supply good quality and good price to our customers. |

Customer Visit & Our Service

| (A) Pre-sale services: Act as a good adviser and assistant of clients, enable them to get rich and generous returns on theirinvestments. 1.Select equipment model;2.Design and manufacture products according to clients' special requirement;3.Train technical personnel for clients;4.Services during the sale; |

| (B)Provide considerate services to minimize clients' worries: 1.Assist clients to prepare for the first construction scheme;2.Install and debug the equipment;3.Train the first-line operators;4.Examine the equipment;5.Take initiative to eliminate the troubles rapidly;6.Provide perfect service;7.Provide technical exchanges. |

Packing and delivery

| Packaging Details:We will make different packaging according to different machine sizes standard international export packing,container, wooden box.Delivery Time:We will customize according to the actual needs of customers. Senior designers start to design the plan. After receiving the deposit, we will complete the delivery within 15 to 25working days. |

FAQ

| Q: For providing you the suitable quotation we need to know the following information:A:1. What is the raw material?2. What is the capacity per hour you required ?3. What is the maximum input size of the raw material ?4. What is the final briquettes size and shape you want? Once we get your answers, I can provide you the best quotation immediately. Remarks: The price will depend on different models Q: What about Warranty of the products ? A:Gongyi hengchang machinary grants our customers a twelve-month-period warranty from the date of delivery for machines exported from us. During the warranty period, in case any defect of material or workmanship occurred with spare parts in norma operation,we will at our discretion replace or repair the defective parts freely. |

Our Contact

Send now